Aerospace Connectors

By Rémi Antoine | November 11, 2021

By Rémi Antoine | November 11, 2021

Space is a challenging environment for electronic systems and components - ultra-high reliability is the top priority – which is why key players use connectors from C&K.

Space has long held a fascination for us Earth-dwellers. It‘s a field of observation and exploration with technological advances related to the conquest of Space. Don’t we say that “Space is the border of infinity…”

For any space application, the number one criterion for component selection is reliability. The distance does not allow any defect and everything must be perfect – and small, but vital, components such as connectors must therefore be carefully specified and designed.

As C&K’s main market for connectors is space, all of its connectors are designed to be reliable in extreme conditions, and are tested and certified appropriately.

The connectors are chosen by space agencies around the world for demanding applications in satellites, launchers, telescopes and other spacecraft. The components are qualified to ESA-ESCC, MIL-M24308 and GSFC-311P specifications.

To ensure they operate reliably in space, the choice of materials in the connectors is important. The main criteria’s in this selection, are that they exhibit no outgassing, resistance to temperature variation, very low magnetism and low electrical contact resistance.

C&K has a deep understanding of the launch and space environment, and our portfolio of connectors are designed to withstand everything that a space mission can throw at them.

C&K manufactures D-Sub (D*M and D*MA), Combo D, Micro-D and Micro Strip formats as well as accessories such as backshells, screw-locks, interfacial seals and retention tools.

Complementary, we suggest useful unique design product like:

MDMA: Micro-D connector with removable crimp contact allow customer to create their own cable harness - this is a feature not currently offered by any other vendor.

C&K has developed a system of crimpable and removable contacts with a retention clip, which replaces the usual “solder bucket” or “wired” terminations. This gives several key benefits:

- The harness length is flexible, and can be chosen to exactly suit the application – saving valuable weight for a space mission.

- It is not necessary to use shrinkable tube.

- Customers can create their own custom harness, with their choice of different wire types and sizes for each contact, if required.

By ensuring only the required wires are used, there is a cost reduction for the harness manufacturer.

SpaceSplice™: One way and 4 ways connectors to link wires with standard solution with removable crimp contact.

Useful for thermistors, heater, MIL…

Benefit:

- Replace hand splice process by standard solution

- Reduce labor time

- Easy to use

- Compact format

- Stackable

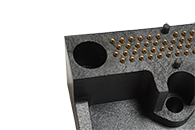

Interposer: Board to board connection with custom solderless solution according to space use.

Technology use electrical contact function decoupled from the pressure applied by spring.

Benefit:

- Solderless spring load contact

- Flexible design

- Easy build interposer concept allow to mix and match option to create the interposer you need

- Stable contact resistance

High reliability and quality are critical when choosing devices for space applications, along with the reputation of the manufacturer. With our 40 years certifications and our long history of delivering products for space applications, C&K is the natural choice.

For a high-profile mission, everything must be perfect. C&K’s reliable connectors will help keep it that way.